Zircon sand, also known as zircon sand and zircon stone , is a mineral mainly composed of zirconium silicate. Pure zircon sand is a colorless and transparent crystal. It is often dyed in yellow, orange, red, brown and other colors due to different origins, types and amounts of impurities. The crystal structure belongs to the tetragonal crystal system , with a square pyramidal column shape and a specific gravity. 4.6~4.71. The change of specific gravity is sometimes related to the composition and alteration state . The cleavage of zircon is incomplete. The uniform Mohs hardness is 7~8, the refractive index is 1.93-2.01, and the melting point ranges from 2190~2420 depending on the impurities contained. Fluctuate within ℃.

Zircon is a mineral composed primarily of zirconium, silicon and oxygen that crystallized from magma when igneous rocks were formed. Zircon is also found in dikes and metamorphic rocks . It belongs to the tetragonal crystal system , often in the form of well-developed cone-shaped small tetragonal prisms, and also in irregular granular shapes. It is brittle and has a shell-like fracture. It is a high-quality refractory material. Most of them coexist with ilmenite , rutile , monazite , xenotime , etc. in seaside sand, and are obtained after separation by water separation , electric separation , magnetic separation and other mineral processing processes.

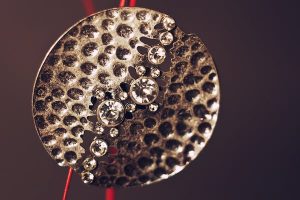

Zircon sand (zircon stone) is the December birthstone, symbolizing success. (The December birthstone also includes turquoise and lapis lazuli .) Its English name is Zircon. Zircon is the name of the mineral. It was formerly known as zircon and hyacinth stone . The transparent ones are called gemstones and are called zircon gemstones . It is one of the oldest minerals on the earth. As a silicate mineral, its chemical properties are very stable, so it has become the most important dating mineral in isotope geochronology . It is the oldest zircon (Zircon) that has been measured. 4.3 billion years ago.

physical properties #

The crystal is short columnar, usually a polygonal shape of a tetragonal prism, a tetragonal bipyramid or a complex tetragonal bipyramid . Due to different formation conditions, the crystal morphology is different. For example, zircon tetragonal bipyramids in alkaline igneous rocks develop into a biconical shape; zircon cylinders and cones in acidic igneous rocks develop into a columnar shape; zircon cylinders in neutral igneous rocks develop into a biconical shape.

The surface is developed, and a complex tetragonal bipyramid appears, so the crystal shape of zircon can be used as a typical characteristic. Zircon sand (zircon stone) comes in various colors, including purple-red, yellow-brown, light yellow, light red, green, gray, colorless, etc., with diamond luster . Moss hardness is 7.5~8, specific gravity is 4.4~4.8. The beautiful and transparent zircon can be used as a gemstone.

It emits yellow light under X-ray irradiation, weak yellow light under cathode rays , and bright orange-yellow light under ultraviolet rays.

Under a polarizer : colorless to light yellow, with strong dispersion and high refractive index. No=1.91~1.96, Ne=1.957~2.04. The refractive index of the homogeneous body decreases, N=1.60~1.83.

Melting point 2340~2550℃. Under oxidizing conditions, it is stable at 1300~1500℃; it decomposes at 1550~1750℃ to generate ZrO 2 SiO 2 . The linear thermal expansion coefficient is 5.010-6/℃ (200~1000℃), and it is resistant to thermal shock and has good stability. It does not react with CaO, SiO 2 , C, Al 2 O 3, etc. at high temperatures . It has strong resistance to slag corrosion and does not stick to molten steel.

Industrial applications #

Zircon sand ( zircon stone ) is extremely resistant to high temperatures, with a melting point of 2750 degrees Celsius. And resistant to acid corrosion. 80% of the world’s refractories are directly used in the foundry industry, ceramics, glass industry and the manufacture of refractory materials. A small amount is used in ferroalloy, medicine, paint, tanning, abrasives, chemical and nuclear industries. A very small amount is used to smelt zirconium metal .

Zircon sand containing 65 to 66% ZrO 2 is directly used as a casting material for iron metal in foundries because of its melt resistance (melting point above 2500°C) . Zircon sand has low thermal expansion , high thermal conductivity , and stronger chemical stability than other ordinary refractory materials . Therefore, high-quality zircon sand has good bonding properties with various other adhesives. And used in the foundry industry. Zircon sand is also used as bricks in glass kilns. Zircon sand and zircon powder mixed with other refractory materials have other uses.

Zircon sand ( zircon stone ) is used in refractory materials (called zirconium refractory materials, such as zirconium corundum bricks , zirconium refractory fibers ), sand for molds in the foundry industry (precision casting sand ), precision enamel appliances, and also used in In the production of glass, metal ( zirconium sponge ) and zirconium compounds ( zirconium dioxide , zirconium oxychloride , sodium zirconate , potassium fluozirconate , zirconium sulfate, etc.). It can be used to make zircon bricks for glass kilns , zircon bricks, ramming materials and castables for steel barrels ; it can be added to other materials to improve its properties. For example, adding zircon sand to synthetic cordierite can broaden the cordierite’s properties. sintering range without affecting its thermal shock stability ; adding zircon sand to high alumina bricks to produce anti-flaking high alumina bricks, the thermal shock stability is greatly improved; it can also be used to extract ZrO 2 . Zircon sand can be used as high-quality raw sand for casting , and zircon sand powder is the main component of casting coatings.

Zircon sand ( zircon stone ) and dolomite react together at high temperatures to form zirconium dioxide or zirconium oxygen (ZrO 2 ). Zirconium oxide is also a high-quality refractory material, although its crystal form changes with temperature. Stable zirconium oxide also contains a small amount of magnesium, calcium, scandium or yttrium oxide. The melting point of stable zirconium oxide is close to 2700. It is resistant to thermal shock and is less reactive than zircon in some metallurgical applications. Stable zirconium dioxide has low thermal conductivity. In industrial zirconium dioxide, hafnium dioxide is harmless when used as a refractory material.

Zirconium in the form of metal is mainly used in the chemical industry and the nuclear reactor industry, as well as in other industries that require corrosion resistance, high temperature resistance, special fusion properties or special neutron absorption. In the United States, about 8% of the total consumption of zirconium is used. For these industries, the only meaningful application of hafnium metal is in the nuclear reactors of warships.

Zirconium metal is obtained by a multi-stage refining method. Initially, zirconite reacts with coke in an electric furnace to produce zirconium hydrocarbon, and then is chlorinated to produce zirconium tetrachloride . The magnesium reduction method of zirconium tetrachloride (Thekroll process) involves the reduction of tetrachloride, which places magnesium metal in an inert gas to obtain sponge-like zirconium metal. High-purity zirconium metal can be refined using the iodide thermal dissociation method. In this process, the metal and iodine vapor react at a temperature of 200°C, and the volatile iodine is sent to the connector, making the zirconium become volatile. form of iodine, thereby separating it from most impurities. At a temperature of approximately 1300°C, the iodide is separated on the heated filament. High-purity zirconium is attached to the filament. The released iodine is transferred from the filament and the product is called a zirconium rod.